N.N. ZOUBOV ENGINEERS SMCE Whirlwind Centrifugal Air Classifier

.

How the Whirlwind Air Classifier works.

The materials are fed into the feed spout and fall onto the rotating distributing plate hub. Centrifugal force flings them through ports onto the lower distributing plate. Coarse particles move outward and settle by gravity into the tailings cone to be discharged (or recycled through the mill).

Fine particles are swept up into the separating zone where selector blades keep out oversized fines by centrifugal force. These are discharged with the coarse material and selected fines continue with the circulating air, through the blades and into the fines cone. Fines drop out as the air turns through vanes to return to the main fan.

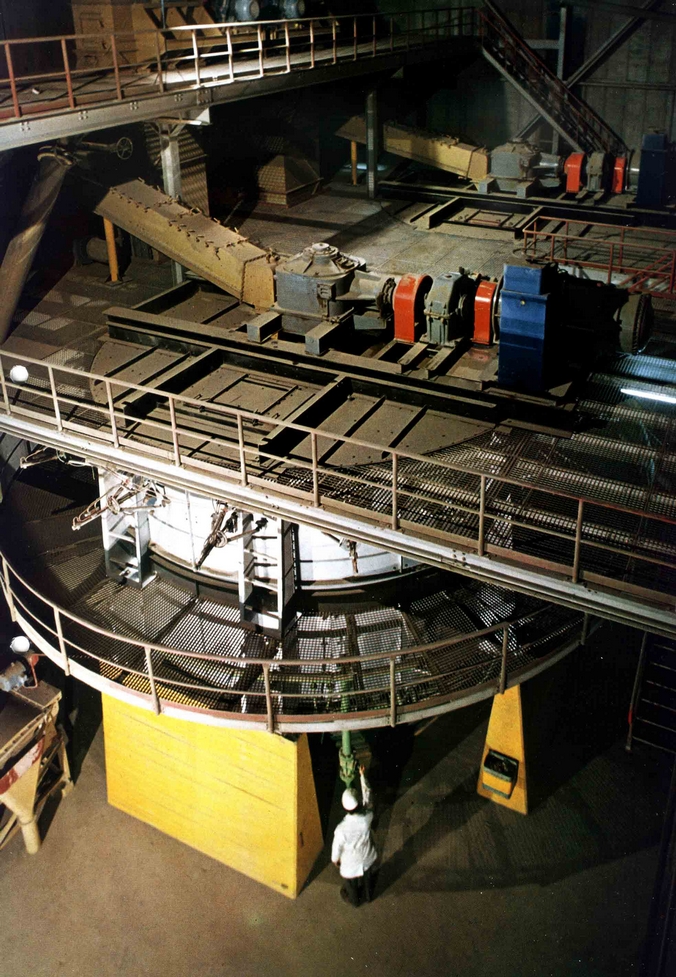

The heart of a modern cement plant.

N.N.Zoubov Engineers SMCE centrifugal air classifiers are sizing machines that separate the fine and coarse particles comprising a dry, pulverized feed mixture.

They can be used in open circuit to obtain a specific particle size distribution of a product or even several products simultaneously: in that case, several air classifiers are used in tandem.

An important application is the dedusting of aggregates or concrete sand products to meet the desired specifications.

However, the air classifier really proves its worth in closed circuit grinding, where it becomes an integral part of the grinding system and governs the fineness and quality of the finished product. In closed-circuit, the entire mill output is fed to the air separator. The air classifier sorts out the fines which have attained the required fineness and the coarse product, or tailings, are returned to the grinding mill (together with new feed) for further reduction.

The procedure permits the mill to operate at its maximum efficiency and leaves to the air classifier, sizing of the required fines. The particle size distribution of the finished product is considerably improved by recirculation of particles in the mill, a reduction in loss of grinding media and wear on mill liners of up to 50 % has been noticed, as well as a decrease in the temperature in the mill.

In fact, a modern cement grinding unit, producing several types of cement, as well as fine specialty grades, is not conceivable without an air classifier to regulate the quality of the finished product, as well as for the specific power consumption saving achieved.

N.N.Zoubov Engineers SMCE centrifugal air classifiers are sizing machines that separate the fine and coarse particles comprising a dry, pulverized feed mixture.

They can be used in open circuit to obtain a specific particle size distribution of a product or even several products simultaneously: in that case, several air classifiers are used in tandem.

An important application is the dedusting of aggregates or concrete sand products to meet the desired specifications.

However, the air classifier really proves its worth in closed circuit grinding, where it becomes an integral part of the grinding system and governs the fineness and quality of the finished product. In closed-circuit, the entire mill output is fed to the air separator. The air classifier sorts out the fines which have attained the required fineness and the coarse product, or tailings, are returned to the grinding mill (together with new feed) for further reduction.

The procedure permits the mill to operate at its maximum efficiency and leaves to the air classifier, sizing of the required fines. The particle size distribution of the finished product is considerably improved by recirculation of particles in the mill, a reduction in loss of grinding media and wear on mill liners of up to 50 % has been noticed, as well as a decrease in the temperature in the mill.

In fact, a modern cement grinding unit, producing several types of cement, as well as fine specialty grades, is not conceivable without an air classifier to regulate the quality of the finished product, as well as for the specific power consumption saving achieved.

During the assembly, each part is carefully tested and controlled.

The general aspects of our air classifier are well known, But how many of you know exactly how much care is taken by the technicians at N.N.Zoubov Engineers SMCE to offer you the air classifier, which will fulfill your demands, Yes, and an output which will be even greater than your expectations.

Thanks to continuous research and development for over a century, the N.N.Zoubov Engineers SMCE air classifiers are among the world's best of this special type of machine for the cement, lime and ore industries.

N.N.Zoubov Engineers SMCE designs its air classifiers to perform with absolutely minimum disruption to their owners' operations, Today, there are N.N.Zoubov Engineers SMCE machines that have run continuously for more than 70 years and replacement parts are always in stock.

Indeed the effective life of an N.N.Zoubov Engineers SMCE air classifier is as often measured in decades as in years, Our philosophy has always been, "when in question, overbuild".

We incorporate in our mechanisms, Gleason type spiral bevel gears and pinions, with carburized and hardened teeth which are designed to transmit much more than the maximum horsepower ever absorbed by the air classifier.

Bearings are over-dimensioned as well to guarantee long years of trouble-free operation.

N.N.Zoubov Engineers SMCE has designed the air classifiers for the easiest possible access for inspection, maintenance and replacement of parts, as in the long run this pays big dividends on the slightly extra cost of construction.

This is why practical operations appreciate N.N.Zoubov Engineers SMCE equipment, and why many will have no other.

Each machine's assembly combines heavy " bullwork " with extensive hand craftsmanship, N.N.Zoubov Engineers SMCE excellent reputation for reliability stems from our insistence upon close tolerances, inspections and manual adjustment of every fitted part. The " human factor " is still very much a part of our manufacturing process.

A wide choice of sizes and capacities.

N.N.Zoubov Engineers SMCE whirlwind classifiers come in 14 sizes ranging from 20 inches (508 mm) to 26 feet (7 925 mm) in diameter.

From the small laboratory machine producing several hundred lbs/h to our biggest model having an output of over 400 t/h of finished product and a maximum feed capacity of 3000 t/h. They produce the desired fines in sizes from 40 to 400 mesh (420 to 37 micron).

There is a science to selecting the correctly sized and equipped air classifier for the job. The best procedure is to work in concert with N.N.Zoubov Engineers SMCE to determine the model you need.

It's a fairly easy matter, given limited experience, to oversize or undersize a classifier for one's application. An undersized machine will either produce the desired tonnage at the sacrifice of the correct fineness or vice versa. An oversized model is simply a waste of money.

The dependable, rugged mechanisms of our air classifiers feature automatic oilers for lower bearing lubrication, and a series of optional items as temperature probes for lower bearing and gear case, automatic grease lubrication system, vibration detector, etc.

An additional area for critical decisions is the selection of proper construction materials to assure that the classifier will withstand abuse from the materials it processes.

N.N.Zoubov Engineers SMCE has used almost every available wear-resistant material in their air classifier and offers liners that are most appropriate for the materials processed.

N.N.Zoubov Engineers SMCE air classifiers operate trouble-free for years with only the simplest routine maintenance. If ever a replacement part is needed, we'll have it on its way to you fast. Most parts are in stock. If the one you need is, you can expect to have it in 48 hours. Specially manufactured replacement parts are available in minimal turnaround time.

With every N.N.Zoubov Engineers SMCE air classifier comes to the assurance that a worldwide organization stands behind our guarantee of excellence.

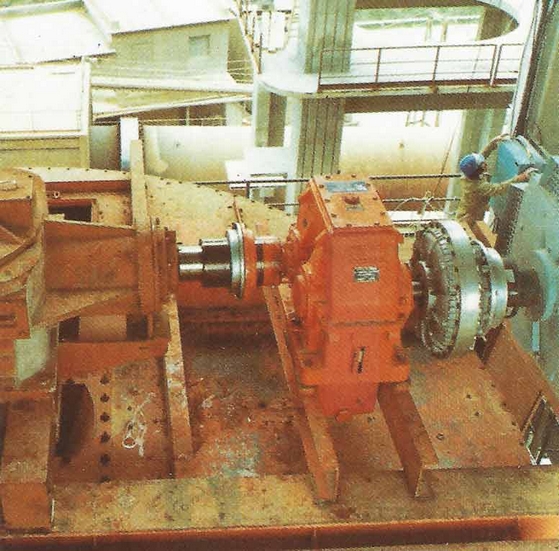

Transmissions.

1. Drive through reduction gear box.

For bigger air classifiers (20' darn up) and high-speed motors (1500 RPM for 50 Hz and 1200 RPM or 1800 RPM for 60 Hz) the most practical drive is through an Intermediate gearbox. The motor is coupled to the high-speed shaft through a flexible coupling and the air separator's shaft is coupled to the slow speed shaft through a flexible coupling.

2. Direct drive.

This drive is suitable for slow speed slip-ring motors 600 RPM (50 or 60 Hz) coupled to the horizontal shaft of the air classifier through a flexible coupling (For 20' diam. air separators and up).

This coupling can be of the" rubber tire" type which gives much flexibility to the drive and absorbs the shock at start-up.

3. V-belt drive.

V-belt drives are most commonly used on all smaller sizes of air classifiers from 20" to 18' in diameter.

For bigger sizes (20' and up) a jackshaft should be used on the driving pulley to prevent too much effort on the motor's shaft bearings.

4. Hydraulic couplings.

On all drives incorporating a high-speed motor (1200 - 1500 - 1800 RPM) a certain advantage can be gained by installing a hydraulic coupling, which allows the use of a squirrel cage motor instead of a slip-ring motor in all cases where a smoother start-up or lower power peak at start-up is desired.

Specifications.